These joints are not generally pressure-actuated. Sometimes its the little things that make all the difference.

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

I am not a big fan of full face gaskets.

. In Parr flat gasket closures the gasket is held in a recess in the vessel cover. The flange class or pressure rating system extends to gaskets designed for those flanges. Ring-joint gaskets are commonly used in grooved flanges for high-pressure-piping systems and vessels.

Per this for 12 bolt the E dimension is 58 gasket width is 1 14 and with a 58 hole the ligament is 516. At the inside edge the pressure is the pressure in the pipe. Jacketed variants push that principle in a different direction by adding special fillers including graphite to the mix.

Those shown in the figure above are the twelve sections of the code. It created an seal with no pressure. Ad Fast lead times.

Effective gasket widths are given in various sections of the ASME Boiler and Pressure Vessel Code. Read customer reviews find best sellers. So for example a class 150 gasket is designed to seal under a load of up to 150 lbs of pressure in a class 150 flange.

The overall pressure rating of the gasket ultimately depends on the material used for the gasket and the operating temperature. Pressure Vessel Gaskets must handle the elevated steam and. Standard Custom Designs including Quick-Open ASME available Engineer Support.

Gasket design for pressure vessel. The decision as to which standard is to. Flexitallic Gasket Design Criteria man- ual offers the engineer and end user assistance in meeting the goal of providing fundamentally sound static sealing practice.

To properly design a pressure vessel it is necessary to understand Section VIII of course and additionally the designer will need to be familiar with Sections II V and IX. A gasket is a compressible material or a combination of materials which when clamped between two stationary members prevents the passage of the media across those members. Boiler and Pressure Vessel is divided into the following sections.

MhT is measured at the point 13 up the triangle the centroid of the force. Gasket Resources is a full service gasket manufacturer with test labs technical support in-field training and bolted joint failure analysis. This table gives a list of many commonly used gasket materials and contact facings with suggested design values of m and y that have generally proved satisfactory in actual service when using effective gasket seating width b given in the table following.

The traditional and most popular main head gasket for Parr vessels is a flat gasket made of a PTFE fluoropolymer. We design these quite often. The gasket should be attached to the flange surfaces and be compressed to reduce the internal voids and spaces.

You can also reach us by calling 417 863-0077. HT is the average pressure along the length. Various LV modules can be used for the flange gasket bolt calculation varying from a simple rough design to a more complex and precise design.

Pressure Vessel Gaskets must handle the elevated steam and hot water temperatures as well as the maximum design pressure of a boiler to create a positive seal. Their applicable pressure range is from 1000 to 15000 psi. Cleaver-Brooks has taken great care to insure our factory selected and engineered gaskets perform to to.

Finally consider spiral wound gaskets a semi-metallic solution that uses one or more V-shaped inserts to centre the ring and add resilience to gasket materials for high-pressure vessels. The current m and y are difficult to replicate for non-asbestos gaskets and do not consider joint. Gasket materials are selected for their chemical and pressure resistance to the fluid in the pipe and their resistance to deterioration by temperature.

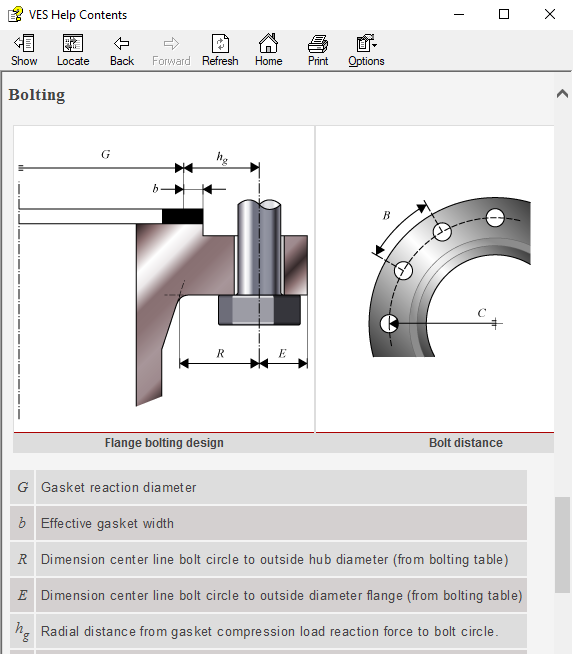

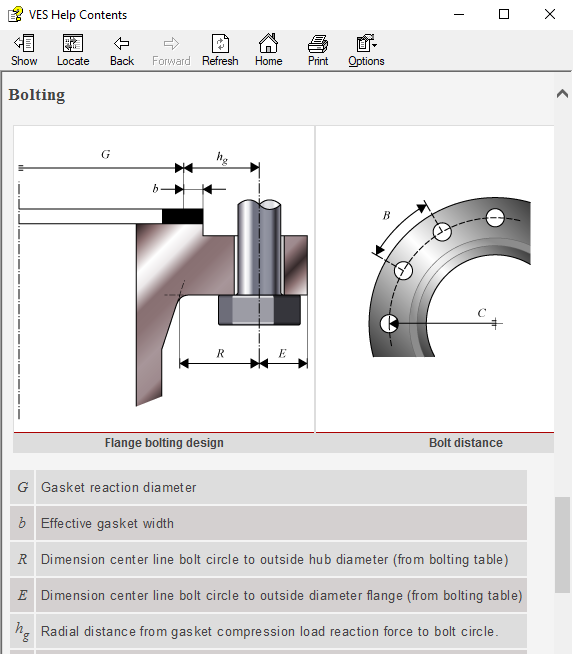

Just fill out this quick form and well get back to you as soon as possible. I am not aware of any real method for calculating the ligament we typically use the E dimensions in TEMA Table D5 as the gasket half-width. The mating lip on the cylinder closes the recess leaving the gasket completely confined with only a small inside.

ASME Boiler and Pressure Vessel Code Calculations. Ad Browse discover thousands of brands. O-Rings Pressure Gaskets.

This load is a design rule not a predictor of. If a pressure vessel is exposed to an internal pressure of. The gasket material selected must be capable of sealing mating surfaces resistant to the medium being sealed and able to withstand the application temperatures and pressures.

Its a measure of 2-D space and the units for area are squared length squared Test Pressure is based on the maximum design pressure of the system and for a pressure vessel based on the. Always Stocked to Reduce Downtime. The ASME rules reduce the width of the gasket.

Ad Millions of Items on One Easy-to-Use Site with Outstanding Customer Service. These gaskets are designed to give very high gasket pressure with a moderate bolt load. The design values and other details.

Flange and gasket calculations. Developed and collated by Flexitallics worldwide team of engineers this publication is the. Confined and Contained Flat PTFE Gaskets for Temperatures to 350 C.

Of the gasket there is no pressure at the gasket OD and thus no leakage. If a pressure vessel is exposed to an internal pressure of 100psi and an external pressure of 35psi the design pressure for the vessel will be an internal pressure of 65psi 65 100 - 35. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors.

New gasket constants to replace the ASME Code m and y are currently being developed by the Pressure Vessel Research Council PVRC and ASME. The design pressure of any pressurised container is the difference between the internal and external pressure. We Are Committed to Making Your Job Easier - Shop our Endless Aisle.

Additional Gasket Design Guide Considerations. A gasket is designed in such way that the flanges should be able to create the specific amount of compressive load on the surface of the vessel.

What Are M And Y Gasket Design Constants And How Are They Used Pumps Systems

What Is A Gasket Functions And Types Of Gaskets Used In Piping With Pdf What Is Piping

P3 Engineering Pressure Vessel Calculation Software Ves

Gasket Characteristics For The Design Of Bolted Flange Connections Of Metal To Metal Contact Type Sciencedirect

Vessel Manways Handholes Pose Special Sealing Challenges

Figure Shows A Pressure Vessel With A Gasketed End Chegg Com

Diagram Of A Typical Reactor Pressure Vessel And Its Sealing Element Download Scientific Diagram

0 comments

Post a Comment